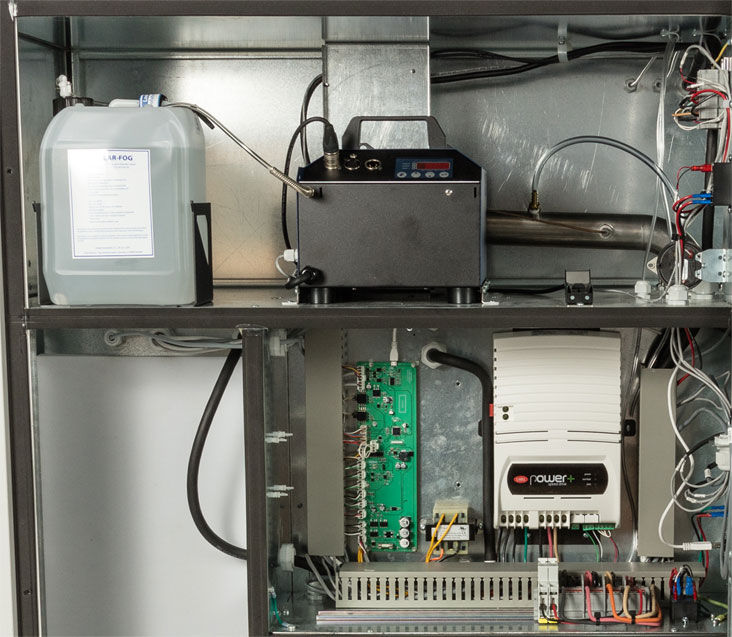

Electrical Component

Mains: 400Vac 3Ph, + Neutral... 240Vac 1Ph option is available

24V transformer included for standard thermostat control. "Y" terminal input as per standard HVAC spec for cooling demand. "C" and "R" terminals for thermostat power supply.

Carel Drive for compressor speed control

Simvac's proprietary advanced heatpump electronic control with Flight Sim specific firmware.